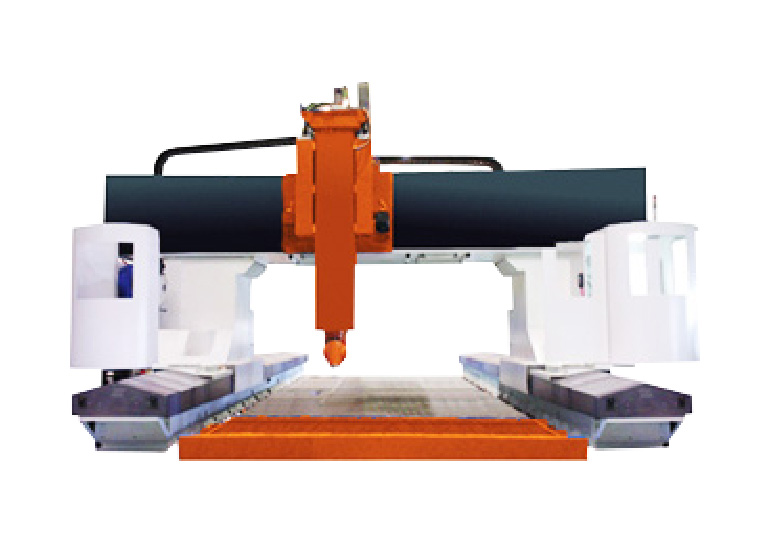

Gantry Type High Speed 5-Axis Ken Machine Center Loader series:

- Moving column type 5-axis machine center

- Spacious Working Area

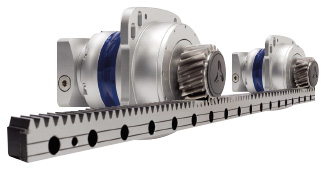

- Dual electronic servo preload rack and pinion system

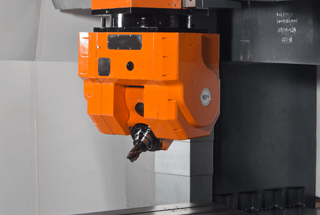

- European High Torque mechanical transmission Milling Head

- 1,200 Nm high torque spindle

- large cnc machine

Spacious Working Area

All the axes of this machine (X/Y/Z/B/C axis) can travel along the moving column.

Also the fixed worktable design ensures this machine is suitable for heavy-duty cutting,

high precision and large component machining, and also provides a spacious working area.

Dual electronic servo preload rack and pinion system

X-axis driven by rack and pinion system, with electronic backlash eliminating technology.

By combining a high-grade decelerator with a high accuracy rack and pinion drive,

this provides high precision, no backlash, low noise, low maintenance, and extended service life.

Mechnical Transmissin 2 axis Milling Head

- High rigidity gear drive, providing a more powerful output

1,200Nm High Torque Spindle

For titanium, Inconel, stainless steel and special steel, alloy steel and other hard materials to milling machining - Closer to the Working Table

B-axis rotation center can shift down, and is equipped with a traditional fork type milling head which can get much

closer to the rotary table surface when performing horizontal machining, effectively maximizing cutting space

European High Torque mechanical Transmission Auto Indexing Milling Head

High rigidity gear drive, providing a more powerful output.

Index milling head up 144 positions every 2.5 ° indexing by automatic rotation(optional: 360 Location indexing every 1 ° or 5 ° per 72 positions), provide producers in processing on flexible use.

1200NM high torque spindle

For titanium, Inconel, stainless steel and special steel, alloy steel and other hard materials to milling machining